Difference between revisions of "SiTCom-B Gallery"

| Line 5: | Line 5: | ||

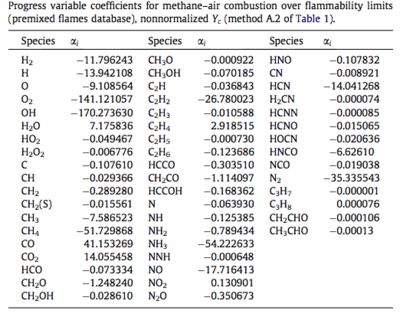

|+ Automated progress variable definition | |+ Automated progress variable definition | ||

|- | |- | ||

| − | | [[File:CF_160_4_YS_TAB. | + | | [[File:CF_160_4_YS_TAB.png|center|400px]] |

| − | | [[File:YC_alpha_optim. | + | | [[File:YC_alpha_optim.png|center|100px]] |

| − | | [[File:OH_Optim. | + | | [[File:OH_Optim.png|center|400px]] |

|- | |- | ||

| Coefficients of the optimized progress variable for CH4/Air combustion | | Coefficients of the optimized progress variable for CH4/Air combustion | ||

| − | | | + | | Progress variable is expressed from all species mass fraction |

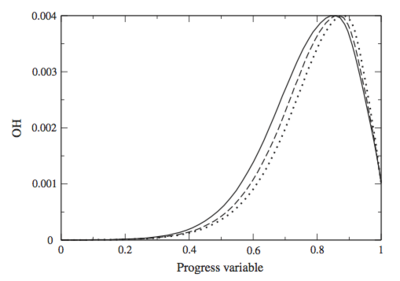

| − | | | + | | OH tabulation valid at all equivalence ratios |

|} | |} | ||

Revision as of 14:29, 24 December 2013

Contents

- 1 An optimization-based approach to detailed chemistry tabulation

- 2 LES of a Trapped Vortex Combustor

- 3 Immersed boundaries in LES of compressible flows

- 4 DNS of a Rapid Compression Machine

- 5 Mixing time-history effects: Flow-Controlled Chemistry Tabulation

- 6 DNS of a non-reacting HIT

- 7 DNS of a non-reacting supercritical mixing layer

- 8 Flame base stabilization in vitiated partially-premixed mixture

- 9 Electric field and edge-flame

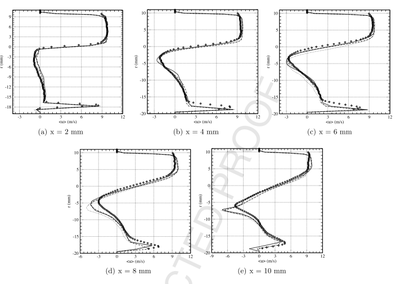

- 10 NSCBC vs 3D-NSCBC in jets

- 11 Impinging round jets

- 12 Ignition of a bluff-body burner

- 13 Bunsen flame

- 14 Jet flame-surface

- 15 Nonpremixed jet flame

An optimization-based approach to detailed chemistry tabulation

Finding a progress variable so that all relevant species can be retrieved from its knowledge, is not always straightforward; specifically for fuel mixtures composed of more than a single hydrocarbon, or for simpler fuels but under conditions where the global reaction progress is not continuous, for instance in the case of cool-flame ignition. To overcome these difficulties, automated methods are discussed to define progress variables in which all species of a chemical scheme, even minor ones, are involved. This is done formulating constraints applied to progress variables definition: they should evolve in a monotonic manner from fresh to burnt gases and species derivative in progress variable-space should stay moderate for tabulation accuracy. This set of constraints is discretized along chemical trajectories observed in laminar canonical flames, to be formulated in terms of an ensemble of inequalities, which are solved using optimization tools. The outcome is a set of weighting coefficients to be applied to every species of the detailed chemical scheme, in order to construct the progress variable-space. The methods have been successfully applied to methane and kerosene premixed flamelets and to n-heptane self-ignition, under conditions with cool-flame effects.

| Coefficients of the optimized progress variable for CH4/Air combustion | Progress variable is expressed from all species mass fraction | OH tabulation valid at all equivalence ratios |

- N. Yi-Shuai, L. Vervisch, P.-D. Tao (2013) An optimization-based approach to detailed chemistry tabulation: Automated progress variable definition, Combust. Flame, 160(4): 776-785.

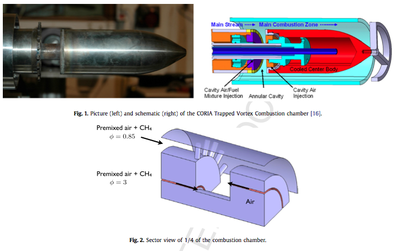

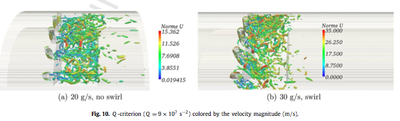

LES of a Trapped Vortex Combustor

| Geometry of the Trapped Vortex Combustion chamber | Q-critrion - Visualisation of the turbulent flow topology | Comparison against experiments |

- C. Merlin, P. Domingo, L. Vervisch (2012) Large Eddy Simulation of turbulent flames in a Trapped Vortex Combustor (TVC) - A flamelet presumed-pdf closure preserving laminar flame speed, Comptes Rendus Mecanique, 340 (11/12), pp. 917-932.

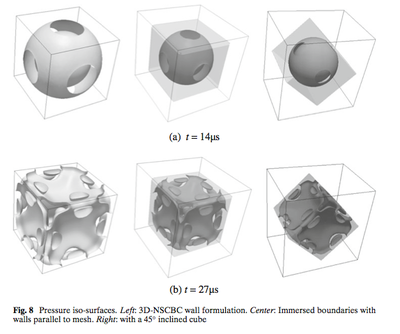

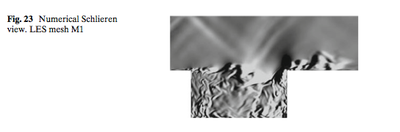

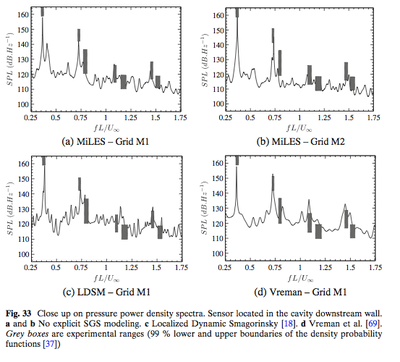

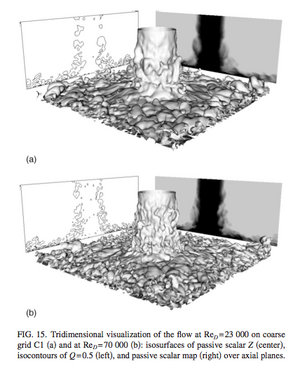

Immersed boundaries in LES of compressible flows

| Pressure wave reflection on inclined walls | Transonic cavity flow simulation | Comparison of pressure spectra against measurements |

- C. Merlin, P. Domingo, L. Vervisch (2013) Immersed Boundaries in Large Eddy Simulation of Compressible Flows, Flow Turbulence and Combustion, 90(1), pp. 29-68.

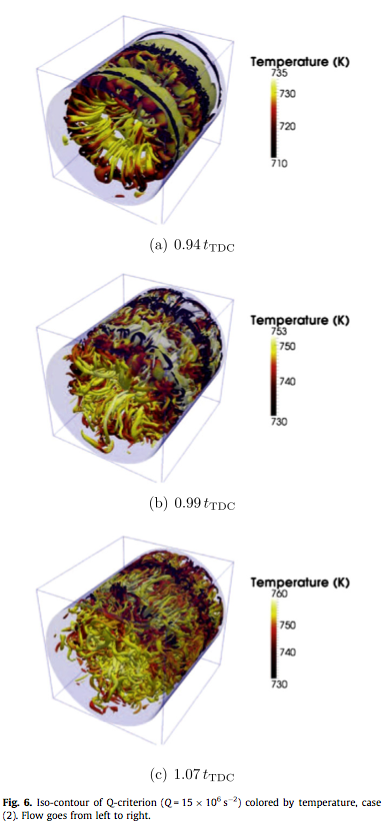

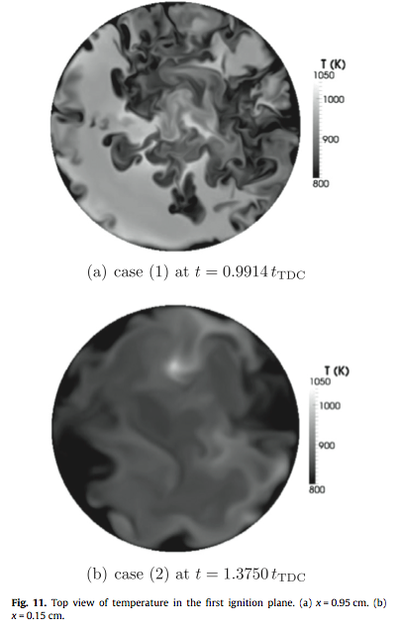

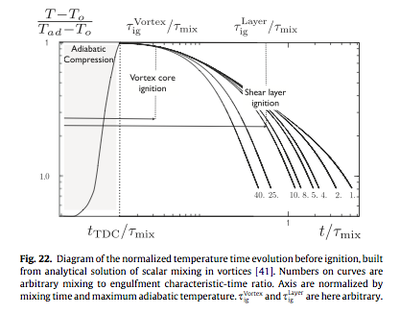

DNS of a Rapid Compression Machine

| Flow injection sequence - Resolution of | Ignition patterns | Regime Diagram |

- G. Lodier, C. Merlin, P. Domingo, L. Vervisch, F. Ravet (2012) Self-ignition scenarios after rapid compression of a turbulent mixture weakly-stratified in temperature, Combust. Flame 159(11): 3358-3371.

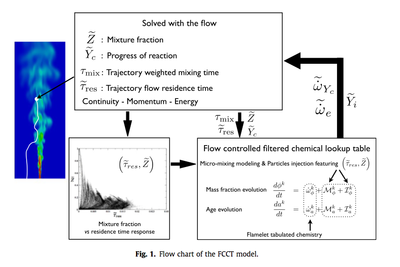

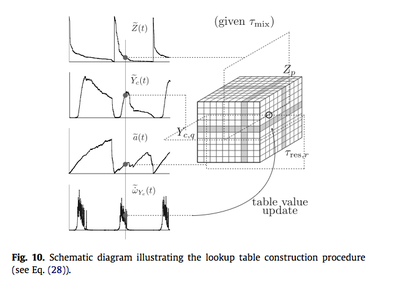

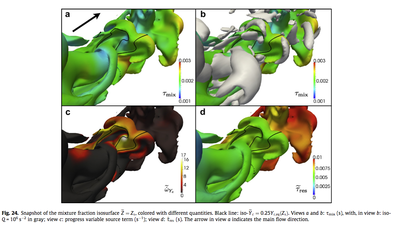

Mixing time-history effects: Flow-Controlled Chemistry Tabulation

| FCCT procedure | Dynamic construction of advanced chemistry tabulation | Turbulent flame response to micro-mixing history |

- N. Enjalbert, P. Domingo, L. Vervisch (2012) Mixing time-history effects in Large Eddy Simulation of non-premixed turbulent flames: Flow-Controlled Chemistry Tabulation, Combust. Flame 159(1): 336-352.

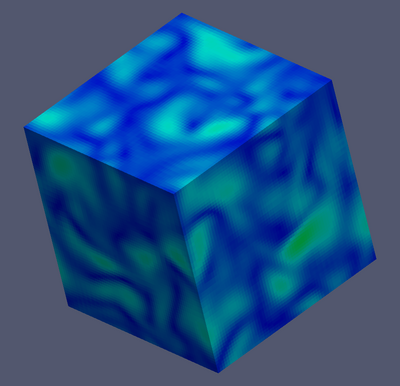

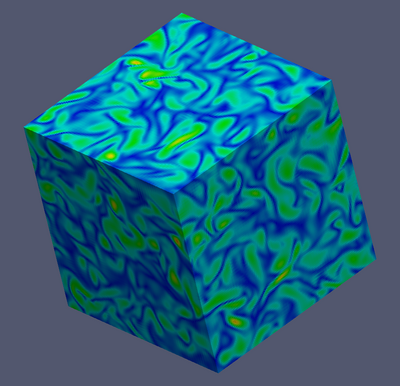

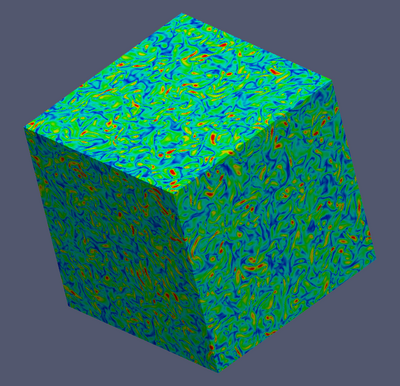

DNS of a non-reacting HIT

This is a very simple DNS computation of a HIT with a constant-properties gas.

The main parameters of the simulation are:

- temporal integration: RK3,

- spatial scheme: 4th order skew symmetric

- no AV.

In this series of computations, the number of cell is increased from 64^3 to 256^3.

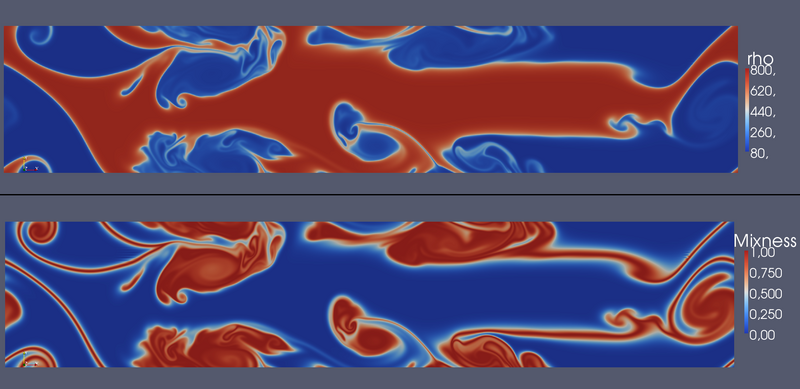

DNS of a non-reacting supercritical mixing layer

This simulation is a DNS of a HIT non-reacting supercritical mixing layer with real-gas properties (equation of state, thermodynamic laws and transport laws).

The main parameters of the simulation are:

- temporal integration: RK3,

- spatial scheme: 4th order skew symmetric

- 2D / Periodic in all directions

- 3.2 Million cells

- EOS: Soave-Redlich-Kwong.

- Transport laws: Chung et al.

The fields that are displayed are:

- up : the density which varies from 80 kg/m3 in the cold stream to 800 kg/m3 in the hot stream.

- down : the mixness ratio which varies from 0 in pure constitutents to 1 for perfect mixness.

Media:supercritical_mixing_layer_mix.avi

This video shows the temporal evolution of mixness ratio during the simulation.

Warning:

- no Artificial Viscosity was used and the mesh was slightly too coarse: a few "wiggles" are visible from time to time near the steepest gradients...

- this video is best visualized with VLC.

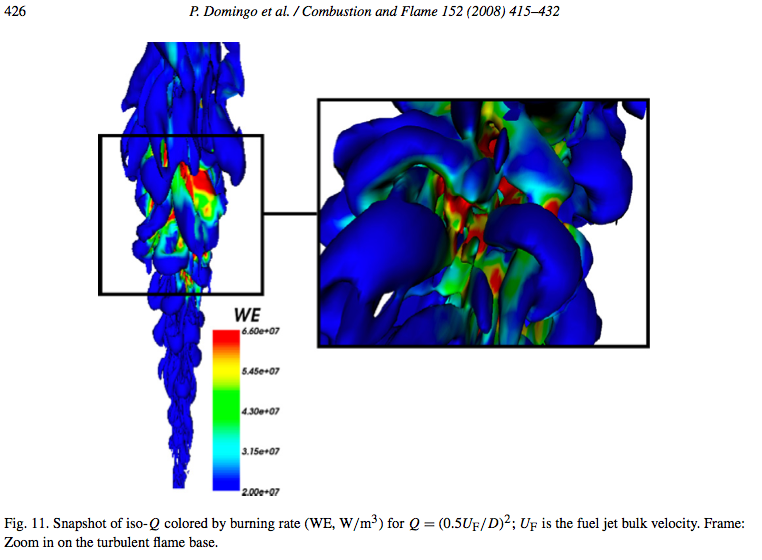

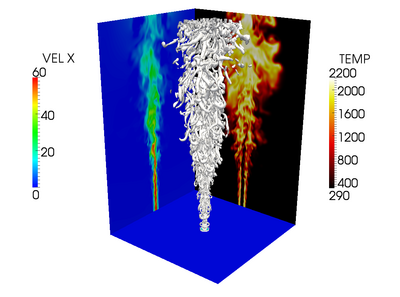

Flame base stabilization in vitiated partially-premixed mixture

- P. Domingo, L. Vervisch, D. Veynante (2008) Large-Eddy Simulation of a lifted methane jet flame in a vitiated coflow Combust. Flame 152(3): 415-432.

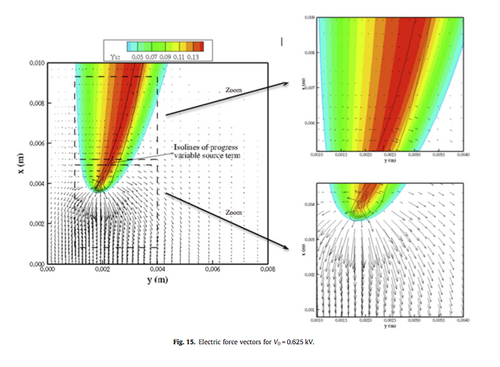

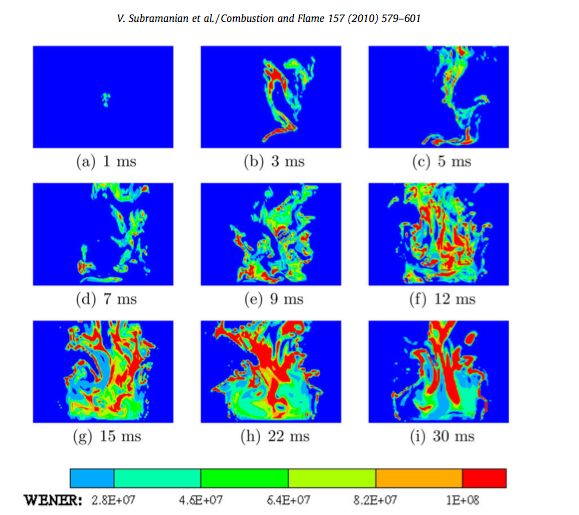

Electric field and edge-flame

- M. Belhi, P. Domingo, P. Vervisch (2010) Direct numerical simulation of the effect of an electric field on flame stability Combust. Flame 157 2286–2297.

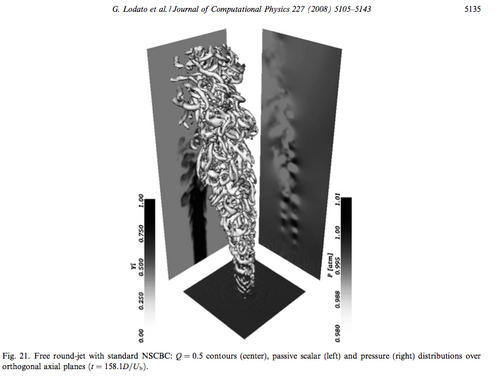

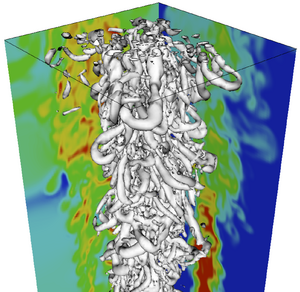

NSCBC vs 3D-NSCBC in jets

- G. Lodato, P. Domingo, L. Vervisch (2008) Three-dimensional boundary conditions for Direct and Large-Eddy Simulation of compressible flows J. of Comp. Phys. 227(10): 5105-5143.

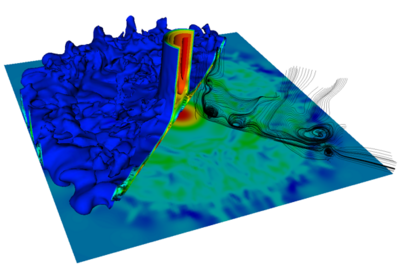

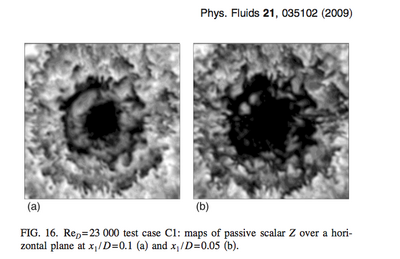

Impinging round jets

- G. Lodato, L. Vervisch, P. Domingo (2009) A compressible wall-adapting similarity mixed model for large-eddy simulation of the impinging round jet Phys. Fluids 21:035102.

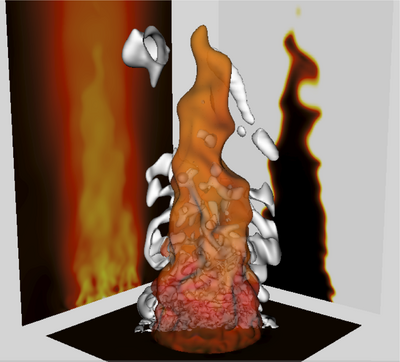

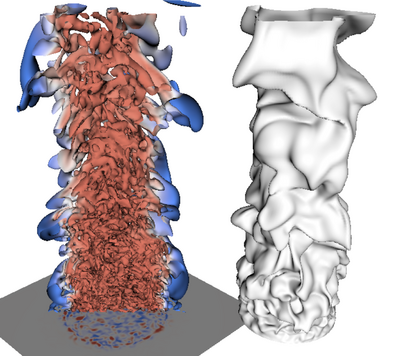

Ignition of a bluff-body burner

- V. Subramanian, P. Domingo, L. Vervisch (2010) Large-Eddy Simulation of forced ignition of an annular bluff-body burner Combust. Flame 157(3): 579-601.

Bunsen flame

- G. Lodato, P. Domingo, L. Vervisch, D. Veynante (2009) Scalar variances: LES against measurements and mesh optimization criterion; scalar gradient: a three-dimensional estimation from planar measurements using DNS In Studying turbulence by using numerical simulation databases XII, (Eds Center for Turbulence Research) Stanford, pp. 387-398

Jet flame-surface

- L. Vervisch, P. Domingo, G. Lodato, D. Veynante (2010) Scalar energy fluctuations in Large-Eddy Simulation of turbulent flames: Statistical budgets and mesh quality criterion Combust. Flame 157(4): 778-789.

- D. Veynante, G. Lodato, P. Domingo, L. Vervisch, E. R. Hawkes (2010) Estimation of three-dimensional flame surface densities from planar images in turbulent premixed combustion Exp. in Fluids 49:267-278.

Nonpremixed jet flame

- G. Godel, P. Domingo, L. Vervisch (2009) Tabulation of NOx chemistry for Large-Eddy Simulation of non-premixed turbulent flames Proc. Combust. Inst. 32: 1555-1551.